Lang Racing

Custom Carbon Fiber Kevlar Reinforced Splitter

Couldn't load pickup availability

What we offer in our custom composite splitter is something we feel is really missing from the open market. When we're at the track we notice that our competitors do one of two things, they either mount plywood/alumalite splitters to their car that they built at home and did all the work to mount, or they buy a "carbon fiber" splitter online that was supposedly designed around their race car. We find that usually these designed carbon fiber splitter packages aren't well thought out and are pretty highly priced for what they are.

Our custom splitter bridges the gap for those who don't have the ability to produce their own custom composite parts but aren't willing to settle for the "off the shelf" bolt on splitters that are often available. It's also for those wise enough to know that cheaper materials aren't ideal for any load bearing application like the aerodynamics of a race car. We wanted to provide a professional level part to the amateur teams without taking up their whole budget.

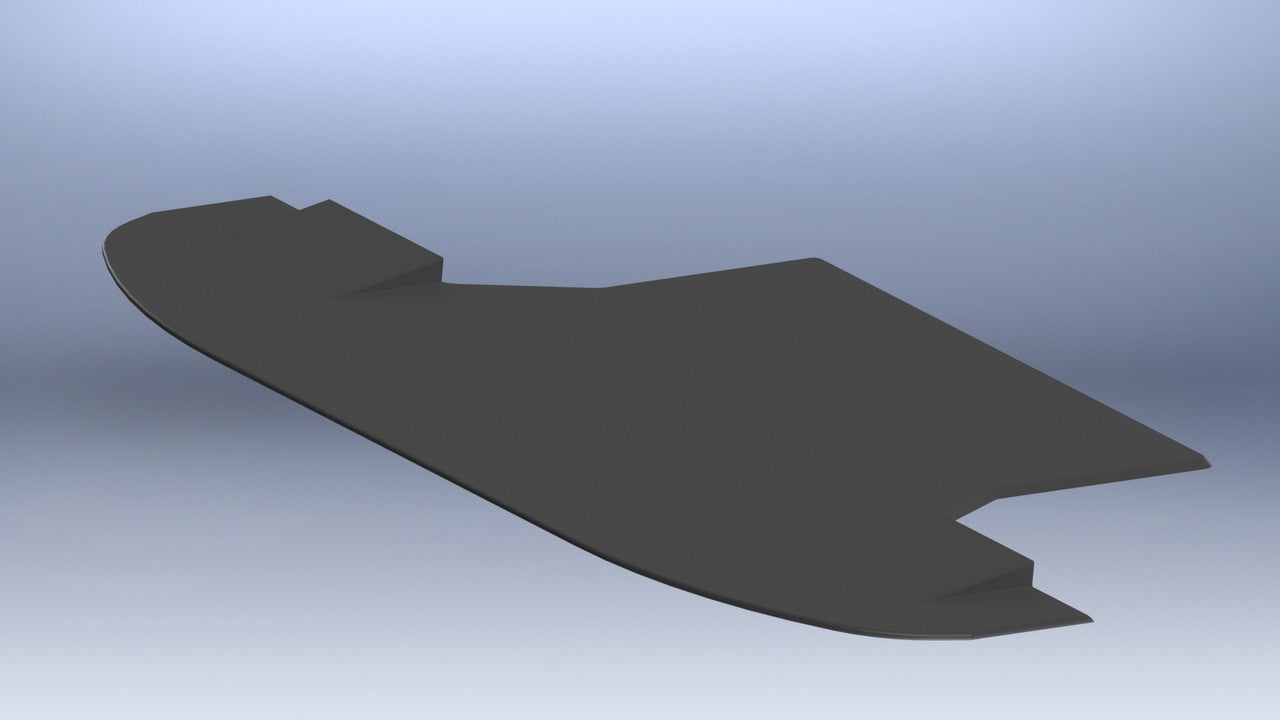

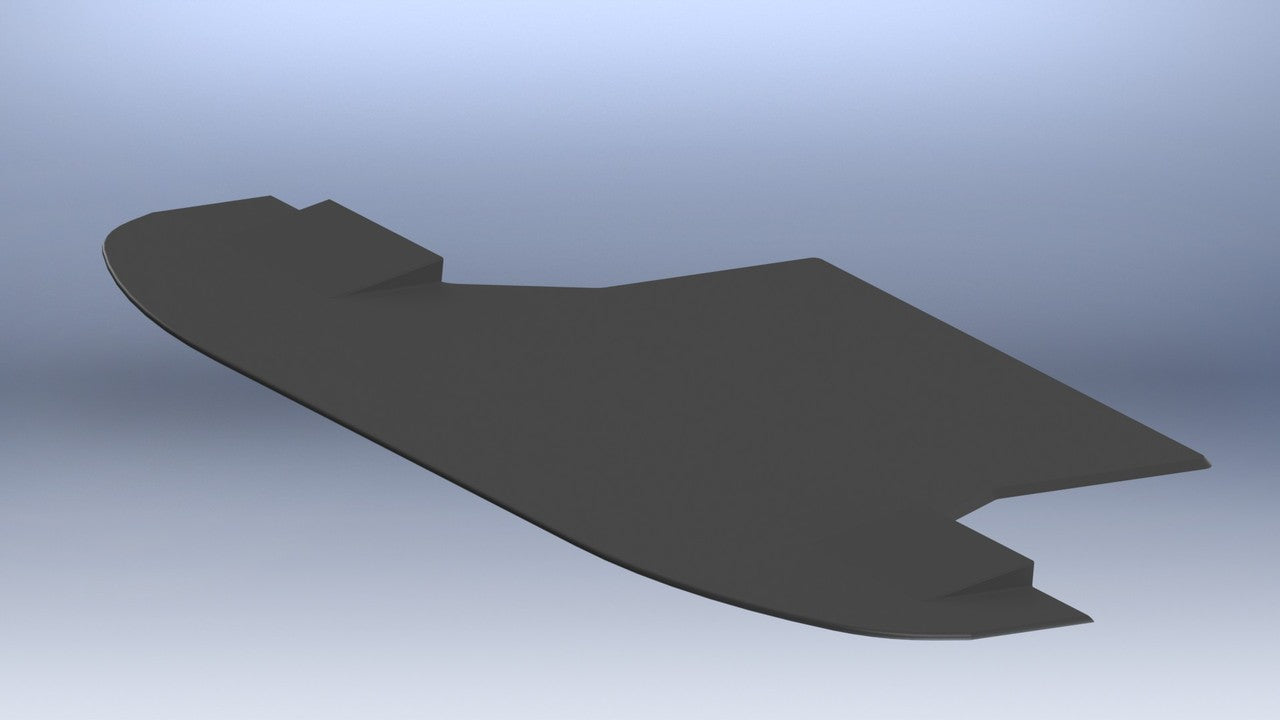

Our splitter mold is designed around fairly wide wheel base E46 M3. The front diffusers are really the only integral part of this particular mold, but their location works for almost every production car.

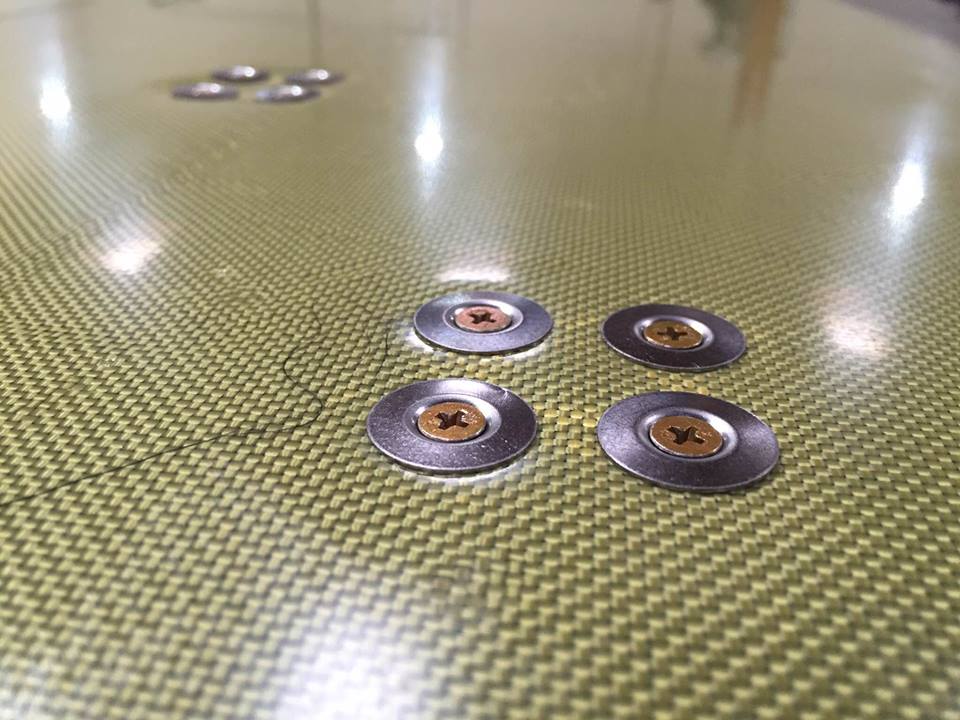

The front diffusers are angled at 11 degrees, located 48" apart and have a width of 11.5". We use a divinycell foam core and sandwich it with several layers of carbon fiber or kevlar depending on the application and the requirements. The standard product includes one layer of kevlar, one layer of carbon fiber, divinycell foam core, followed by two more layers of carbon fiber. This produces a good compromose of weight, stiffness, and strength. We can build stronger or lighter splitters but our base cost is formed around this type of construction. We take your dimensions and form the foam core to that shape then place it in our mold and layup over it. This allows our splitter to have a rounded leading edge and also have the shape that fits your requirements. Our splitters are made with a carbon infusion process to ensure a strong and lightweight part using only epoxy resin.

To get started upload a file with your purchase that includes your desired splitter leading edge shape. If you would like us to provide one of our generic splitters or one of the shapes we use on our BMW race cars that is an available option as well at no additional cost. If you have the ability to do so please download our Solidworks part file and edit it as necessary. You can then upload this file with your purchase to give us the exact design criteria for your splitter. Click here to download this file.

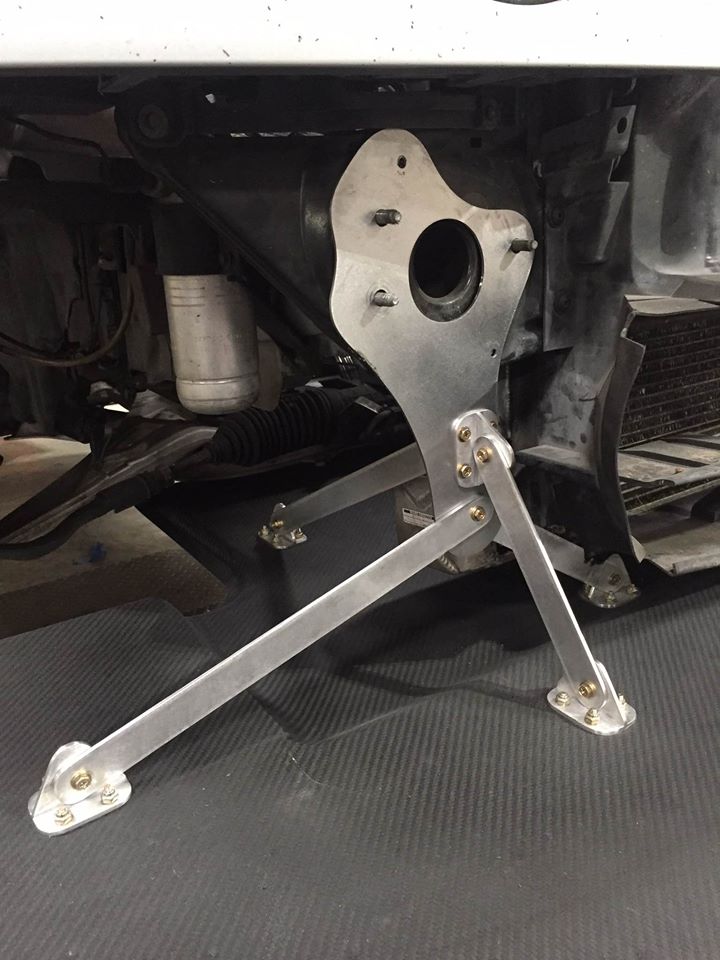

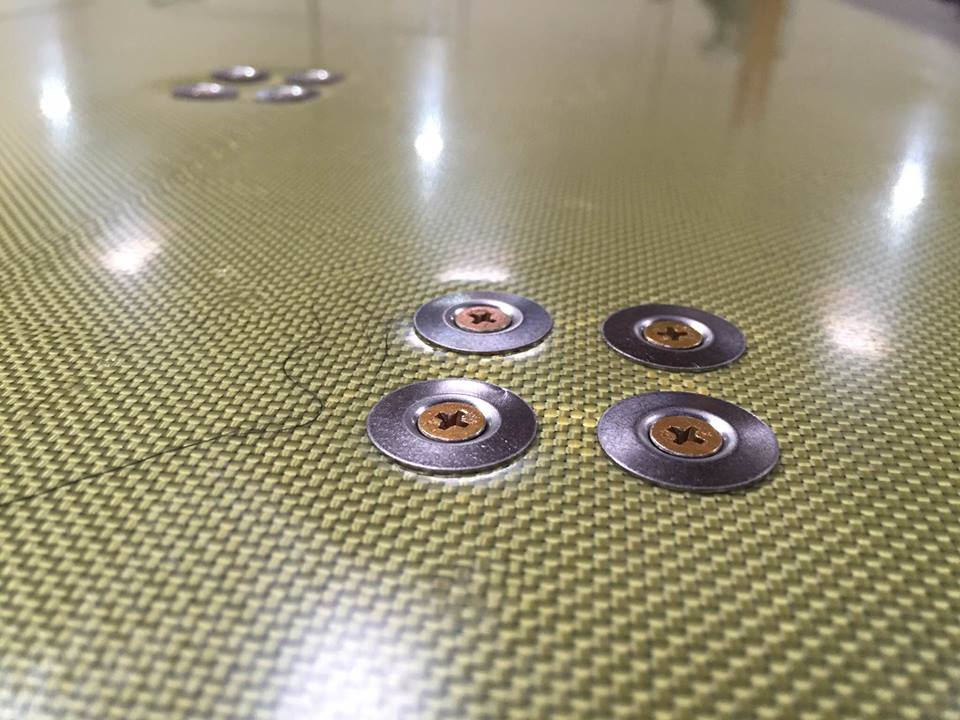

We now have the option to purchase our mounting system. This system is significantly different than anything else out on the market in that it spreads the load out to 4 points for each side of the splitter. The straps are designed to bend if necessary when the splitter is hit. This allows the splitter to move up or back without damaging the actual element. The straps can often be bent back into shape after an incident or replaced very economically if necessary. We use only aircraft grade hardware to assemble these kits.

All parts are manufactured in Irvine California.

Share